Process

Q. What is vacuum impregnation?

A. Vacuum Impregnation is the process of sealing the porosity in castings. The impregnation material is introduced into the porosity within the wall thickness of the casting through vacuum. The sealant liquid is subsequently solidified by heating at elevated temperature. The process is carried out using the Impregseal Dry Wet Porosity Sealing Systems using our world renowned and approved Sealants.

Q. Why does a casting leak on Pressurisation?

A. A Casting leaks on pressurisation due to defects/porosities. Porosities are caused by internal shrinkage or gas cavity, oxide films and inclusions. These are some of the defects which cause a casting to leak on pressurisation.

Q. What is a porosity?

A. Porosity is the defect in the casting caused by shrinkage or gas.The defect will be isolated in case of blowholes or in form of cluster in the case of gas or shrinkage. Porosity can be classified as micro-porosity and macro-porosity.

Micro-porosity is very small, sometimes invisible to naked eye and detectable in radiography. They are interconnected and they are spherical in form.

Macro-porosity are larger defects visible to eye, are spherical or sometimes they are like pipes.

These are two types of porosity- 'Blind porosity' and 'continuous'. These two can be impregnated. We also find 'totally enclosed porosity' which opens up after machining.

Q. Explain the blind, continuous and totally enclosed types of porosity?

A. A Casting wall has two sides, inner side and outer side. If the porosity is open to only one side, it is called open porosity, if it is open two both sides it is continuous type of porosity. If it is not open to both sides and if it is totally inside, it is called totally enclosed type.

Q. So. there is no need to impregnate porosity of totally enclosed type?

A. No. Normally castings are machined and used. When you machine the casting, the totally enclosed porosities open up. Hence, after machining , incase these totally enclosed type porosities open up , or there is a chance of other micro-pores to be connected , then these porosities are also to be impregnated .Also, due to vibration and mechanical work or thermal shock the porosity may become continuous.

Q. I have a good Inspection. I will separate good castings from bad castings. How would impregnation improve casting quality ?

A. Good castings sorted out may also have interconnected porosity inside the wall. Porosity on inner surface is not seen unless you do non destructive X-ray test, Impregnation fills porosity from both sides and salvages even rejected castings. Furthermore, impregnation removes the possibility of human or machine errors to occur during the leak testing, thereby giving 100% quality assurance.

Q. What items and alloys can be impregnated?

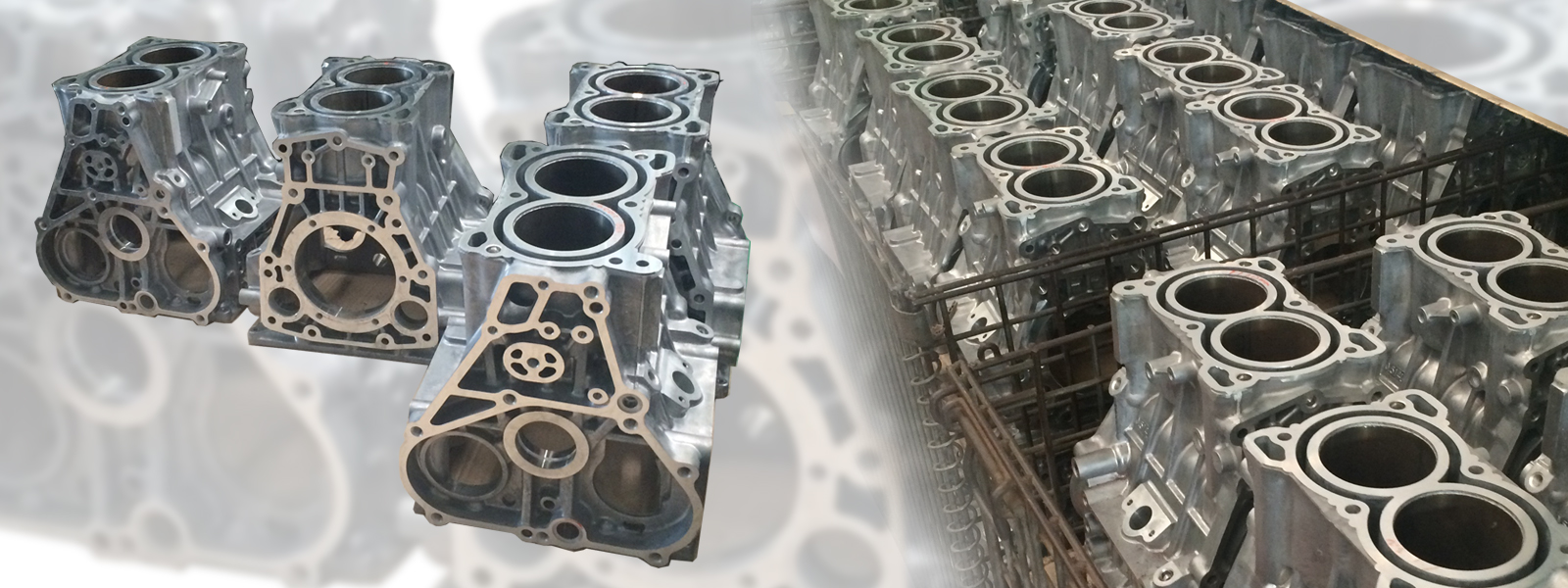

A. All ferrous and nonferrous metals can be impregnated to fill porosity. Iron, Bronze, Aluminium, Zinc, Magnesium, Steel, sintered powder metallurgy products, plastics and alloys of the metal can all be impregnated. Sand castings, gravity and pressure die cast components and forgings can be impregnated to seal porosities and ensure pressure tightness, A wide range of components typically impregnated with our sealants are

|

Aerospace components Air compressors Automotive cylinder heads and blocks Electrical connectors Food processing equipment Filtration equipment Fuel supply systems Hydraulic pumps/valves Process control equipment Transmission housings Wheels Power brakes Thin walled die castings |

Powder metallurgy products

Electronic components Gas and steam fittings Plastic moulds Instrumentation meters and valves Refrigeration components Truck and railway brake parts Cast row hydraulic control. Heat exchangers Ceramic parts Builder's hardware Aluminium compressor castings |

Q. Can I save money, time and energy by adopting impregnation?

A. Yes when you send the impregnated castings to your customer, the chance of it getting rejected at your customer's place due to a leakage is eliminated and you get quality assured. The impregnation cost is only a very small fraction of the cost of re-melting, remaking and other costs. In addition, you save time and energy for recasting and machining. Moreover, the new casting that is made, may again turn out to be a leaker.

Q. When should impregnation be carried out ? Before or after machining?

A. Machining will open inter-porosity. Normally it is preferable to do it after machining unless the castings are subjected to pressure test in cast stage itself. Also, depending upon the history of the casting and also the areas of leakage, you can decide whether to impregnate the raw castings or machined castings.

Q. What is the quality control check for impregnation?

A. Effectiveness of impregnation is checked by impregnating porous test pieces. These are in the forms of Aluminium sintered test rings with a predetermined level of porosity as specified by the test specification of the US MIL 17563 - B test method. These leaking rings are also passed along with the castings to be impregnated, through the impregnation plant. Subsequently, these test rings are tested for leak tightness. Also the actual component is checked by a pressure test. We can successfully Impregseal the components using our world approved Sealants.

Q. What are the size limitations for castings to be impregnated ?

A. There is no size limitations. We have special techniques to impregnate any casting. However, for vacuum impregnation machines, we can go upto 1500 mm diameter and 1500mm height and larger.

We have built machines up to 7000 mm height.

Q. Can you impregnate components of sizes more than 1500 mm diameter and 1500 mm height i.e. large sized castings?

A. Our engineers will advise you regarding our special procedure. Please email us at info@impregseal.com