SPECIAL IMPREGNATION SEALANTS

With the use of the world famous impregnation material TSP range of sealant, Impregseal offers a highly cost-effective solution to the problem of porosity.

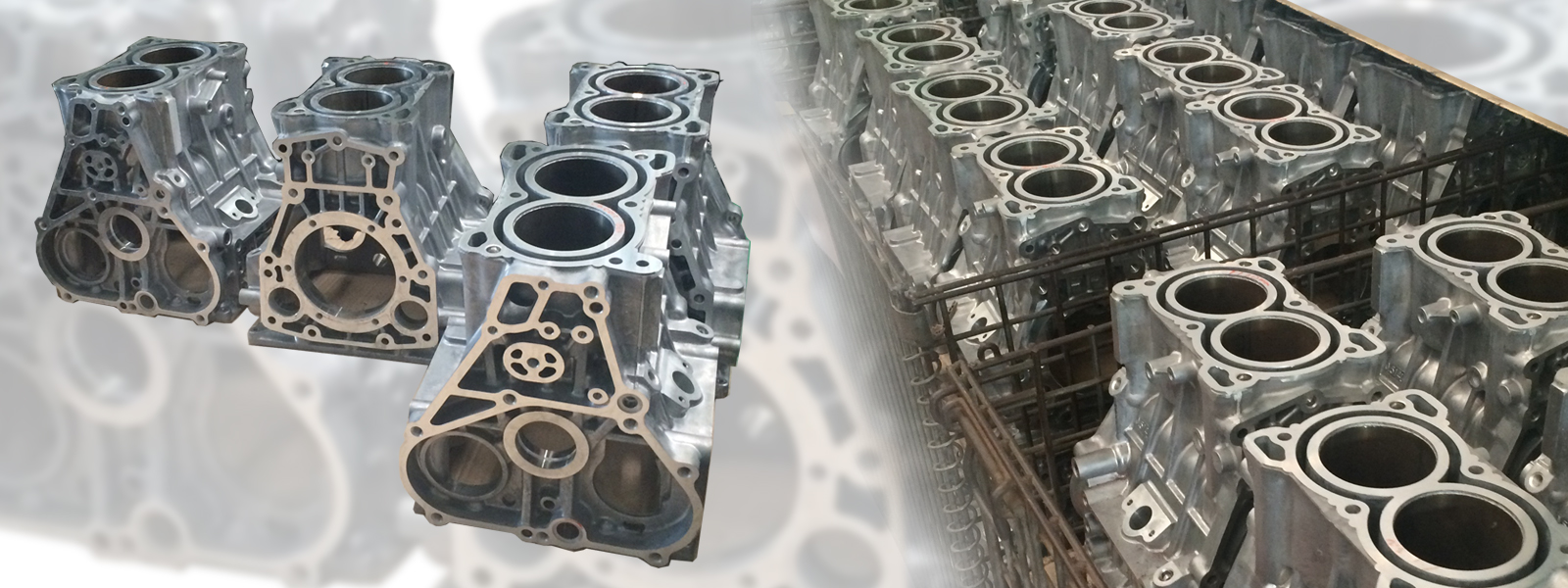

Today’s demanding production techniques and the trend to create lighter alloys of aluminium and magnesium has increased the incidence of micro porosities in metal casting(ferrous & non ferrous). The world has realized that impregnation allows for on time deliveries by reducing production and assembly downtime. This has made, impregnation techniques an accepted process to the foundryman and Technology specified by the design engineer.

The Impregseal range of sealants compliment vacuum impregnation technology worldwide and continue to lead the industry. Our sealants are a cross linking mixture of mono and polyfunctional acrylates and methacrylates. TSP range of sealant does not contain any halogens, solvents or PCBs. Further, our sealants are designed to have the perfect balance of viscosity for effective penetration of porosities, and to achieve excellent adhesion to the inner walls of porosity ensuring a robust seal. The sealants are environment friendly, containing no toxic substances. Exhaustive trials in various demanding applications show that impregnation finds wide applications in metal castings(ferrous & non ferrous), plastic connectors, sintered parts and other porous materials, like wood etc. It is suitable for use in both large batch and lean manufacturing applications, producing consistent high quality performance, whatever the size or nature of the components being treated.

Approvals & Certifications

Our range of Sealants are approved by most major automobile manufacturers and also conform to the stringent quality standards and specifications in international standards such as, UL-87 (Under Writers Laboratory - USA), NSF/ANSI 61 (NSF International USA), US MIL 17563 rev C (US Military specification for Impregnation Sealants).

Our quality management system is certified as per EN ISO 9001:2008

Environmental Thermal & Pressure Conditioning tests conducted as per US MIL 17563 C

| Media | Media Specification | Time (hr) | Temperature (F) | Results |

|---|---|---|---|---|

| Water | N/A | 336 | 212 | No Leakage Noted. |

| Oil | MIL-H-17672 | 336 | 210 | No Leakage Noted. |

| Hydrocarbon Fluid | TT-S-735 | 336 | 73.4 | No Leakage Noted. |

| Carbon Removal | P-C-111 | 0.5 | 73.4 | No Leakage Noted. |

| Lubricating Oil | MIL-L-7808 | 48 | 255 | No Leakage Noted. |

| Turbine Fuel | MIL-T-5624 | 48 | 73.4 | No Leakage Noted. |

| Ethylene Glycol | MIL-E-9500 | 336 | 300 | No Leakage Noted. |

| Hydraulic Fluid | MIL-F-17111 | 336 | 210 | No Leakage Noted. |

| Fuel | ATSM D910 | 48 | 73.4 | No Leakage Noted. |

| Diester Grease | MIL-G-23827 | 48 | 73.4 | No Leakage Noted. |

| 18% Sulfuric Acid | O-S-809 | 2 | 73.4 | No Leakage Noted. |

| Stoddard Solvent | P-D-680 | 48 | 73.4 | No Leakage Noted. |

| Ethyl Alcohol | MIL-E-463 | 48 | 73.4 | No Leakage Noted. |

| Thermal Resistance | N/A | 336 | 300 | No Leakage Noted. |

| Thermal Resistance | N/A | 336 | 500 | Leakage of all samples. |

US MIL Standards Table

Technical Data

Technical data Sheets & Material Safety Data Sheets will be provided on request, contact: info@impregseal.com